A friend recently asked me on LinkedIn about Inventory ABC analysis on Maximo and how to setup physical cycle count. After responding to him, I thought it could be posted on this blog to share with other Maximo users who like to know more about this function.

|

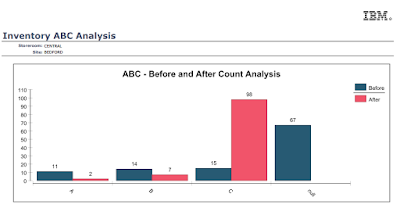

| First page of the ABC Analysis Report |

ABC Analysis is the method of categorizing inventory items into three groups: fast-moving, average, and low moving. This method is commonly used in ERP systems like SAP or Oracle. However, it is less frequently used in Maximo Inventory.

The concept of fast-moving or slow-moving refers to the total financial movement of inventory. For example, if the inventory has 3 items:

- Toilet paper: $2 per Roll, company uses 10 roles/day or $20/day, movement of this item is $7300 per year

- Printer toner: $100 per Each, company replaces them every 2 months, thus movement is $600 per year

- Computer laptop: $2000 per Each, company issues only two items a year, thus $4000 movement a year

Total movement is $13.900

If A, B, C is defined as the items that accounted for the top 30% of the movement, middle 40%, and bottom 30%, Toilet paper is a fast-moving item and belongs to Category A, and Toner is a slow-moving item.

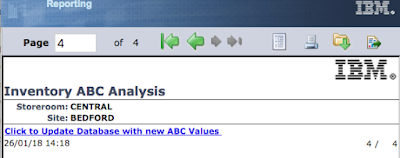

In Maximo, there’s a standard out-of-the-box report for ABC Analysis. After the report calculated the consumption value and produced A,B,C values associated with each item, we can update the ABC values back to the inventory by clicking on the link at the bottom of the list.

|

| Link to update ABC values back to Maximo Inventory Screen |

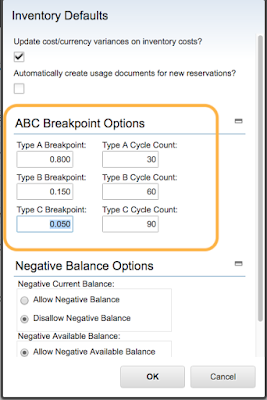

For physical count, we can set in organization settings to define the physical cycle duration for each ABC category so that Maximo will automatically set a due date to do physical count for each item depending on its category. Some companies only carry out physical count as part of inventory/accounting audits, thus they only do it once per year, for the whole inventory, usually before fiscal year-end. Other companies with more mature processes have different cycle counts duration for each category, such as 3 months for fast-moving item, and 1 year for slow-moving items, this varies a lot depending on each industry.

|

| ABC break point and Cycle Count Settings |

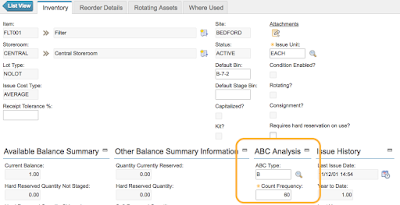

With the Anywhere Physical Count mobile app or other 3rd party mobile solution, the app will download the items that are due to count so that warehouse staff can go out after a specific list of items do a physical check then update the actual count. This value is synchronized to Maximo, and if there is a difference in Maximo’s current balance vs actual count (usually actual count is less than the real balance due to theft, loss, or temporary issues that are forgotten and or issues that aren’t entered into the software), we can run Reconciliation process to update new balance and record the “loss” to shrinkage account.

|

| ABC Type value of an item in the Inventory app |

In practice, many companies prefer to record this “loss” as a standard “Issue” transaction against shrinkage accounts because it is simpler to do so. Besides, if there’s integration with ERP/Finance system, this makes things simpler as the transactions will be posted to the ledger without having to build another interface (Issue transactions and Reconciliation transactions are stored in two different tables). We can also create a logical “Shrinkage” location with the right GL account so the user only has to issue against this location and thus doesn’t have to remember the GL account combination.

Some companies also combine the ABC category with the criticality of items (High, Medium, Low), so in their Maximo system, you will see strange values such as CH, AM, or BL. The idea is for process or safety-critical items, in many cases, even if they are slow moving, it is still important to do frequent physical checks to ensure they are always available to use in case needed.